by Rick Smith

Win2uit Plant Manager

The electronics manufacturing sector is heading into 2026 with real momentum. Global forecasts project growth past $2.3 trillion, driven by AI infrastructure, electric vehicles, and consumer electronics that keep getting smaller and more complex.

But growth numbers don’t tell you how to run your business. What matters is understanding which trends will actually impact your operations, and which ones are just noise.

At Win2uit, we’re in the middle of these shifts every day. Here’s what we’re seeing, what’s driving it, and how manufacturers need to adapt.

Electronics Manufacturing in 2026: In this article:

- Market dynamics and where manufacturing work is moving.

- How AI is changing quality control and predictive maintenance.

- Why nearshoring became operational infrastructure, not just risk mitigation.

- The miniaturization challenge and talent gap in advanced packaging.

- Sustainability moving from marketing to manufacturing requirements.

- Automation is separating industry leaders from followers.

- How prototyping speed became a competitive weapon.

The Market Reality: Where the Work Is Going

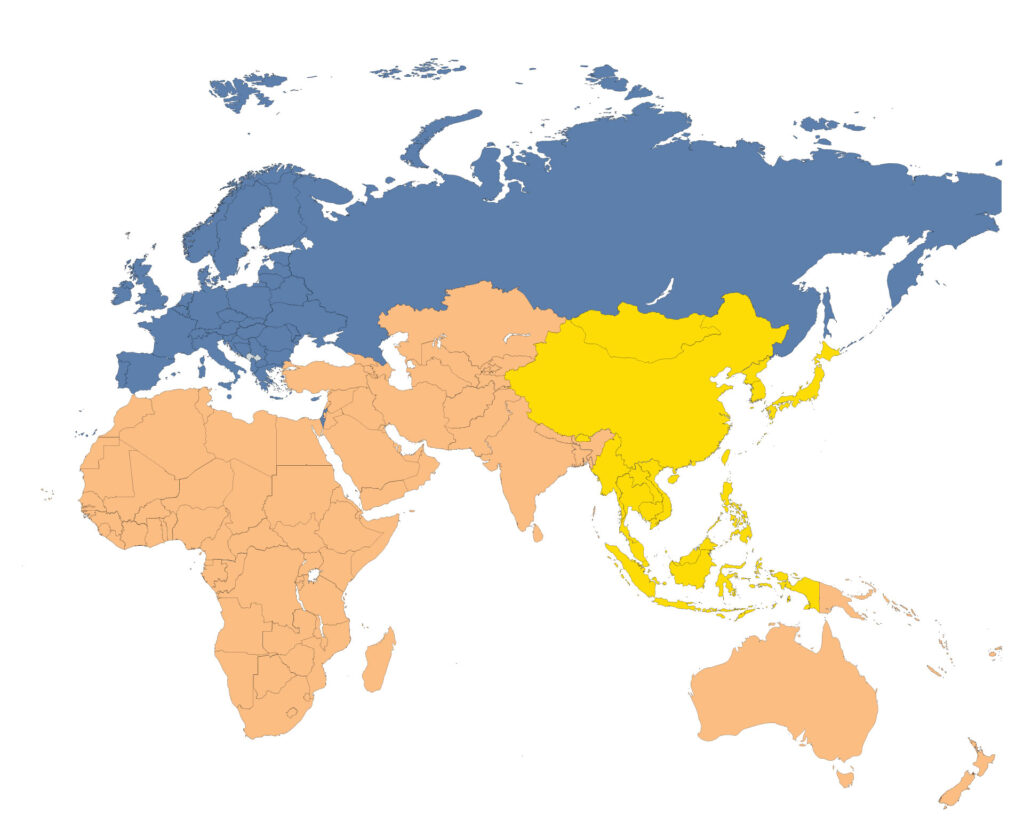

The global electronics manufacturing services market is pushing toward $647 billion in 2025, growing at nearly 6% annually through 2030.

But regional dynamics matter more than aggregate numbers.

Asia-Pacific still dominates production volume. Taiwan’s PCB ecosystem alone is growing 5.8% yearly. China, South Korea, and increasingly Vietnam supply advanced substrates to AI server builders and consumer electronics manufacturers.

North America saw EMS shipments jump 14.9% year-over-year recently, with the regional market exceeding $90 billion. Growth concentrates in reshoring; defense electronics, EV components, semiconductor packaging.

Mexico is capturing automotive and server rack programs under USMCA, becoming critical infrastructure for U.S. OEMs.

Europe focuses on compliance-heavy sectors: medical devices, industrial electronics. Poland and Romania are securing European EV platform work as nearshoring accelerates.

Win2uit’s take: We operate in this evolving landscape daily. Our customers are navigating these regional shifts while managing cost pressures and lead time expectations. Geography isn’t destiny, but it’s strategy.

Trend 1: AI Is Rewriting Manufacturing Operations

Artificial intelligence isn’t future speculation anymore. It’s deployed in production right now.

Where AI Shows Up in Electronics Manufacturing:

- PCB design and layout prediction that auto-generates efficient component placement.

- Signal analysis and thermal modeling that simulate performance before production.

- Vision systems that catch defects human inspectors miss.

- Predictive maintenance that forecasts equipment failures before downtime.

- Digital twins that enable real-time process optimization.

Siemens acquired Downstream Technologies specifically to tighten design-to-manufacturing pipelines. The ROI is measurable: better throughput, higher first-pass rates, fewer surprises.

The gap? Most companies still can’t establish end-to-end supply chain visibility. Gartner estimates 95% will fail at this by 2026.

What Win2uit Is Doing About It

We’ve integrated AI-powered quality control and predictive maintenance into our MES platform. Our systems handle thousands of machine interactions per hour, catching issues before they become yield problems.

The manufacturers winning in 2026 won’t be the ones talking about AI. They’ll be the ones actually using it to improve yield and reduce downtime.

Bottom line: AI deployment separates operational efficiency from operational theater. Implementation matters more than press releases.

Trend 2: Nearshoring Isn't a Trend Anymore, It's Infrastructure

Offshoring used to be the default. Cost efficiency dominated strategy. That’s over.

Why Manufacturing Is Coming Closer to Home:

Geopolitical tensions, pandemic disruptions, and tariff uncertainty triggered aggressive capacity relocation.

- Foxconn built a $383 million board plant in Vietnam.

- Mexico leveraged USMCA to capture automotive and data center work.

- Eastern Europe secured EV platform programs.

The benefits extend beyond risk mitigation:

- 40% reduction in freight lead times.

- Lower inventory risk from shorter supply chains.

- Simplified communication across time zones and languages.

- Faster iteration cycles for high-mix, low-volume work.

The Cost Reality Nobody Talks About

Localized manufacturing costs more in labor. But when you factor in speed-to-market advantages, reduced supply chain risk, and improved customer collaboration, the math changes.

Win2uit’s North American operations deliver turnaround times Asian facilities can’t match; not because we’re faster at assembly, but because we eliminate weeks of freight time and customs complexity.

Success in 2026 means balancing cost with agility. Pure offshoring optimization is a losing strategy.

Need help navigating advanced packaging challenges?

Trend 3: Boards Keep Shrinking. Complexity Keeps Growing

High-density interconnect boards now use microvias and stacked copper layers to pack more functionality into smaller footprints.

Surface-mount technology replaced through-hole components in most applications, enabling unprecedented component density.

The Packaging Revolution

- System-in-package (SiP) integrates multiple components into compact modules

- 3D packaging stacks components vertically for better performance

- Fan-out wafer-level packaging (FOWLP) enables thinner, lighter designs

- 124-layer PCBs (15% more than previous standards) for AI testing equipment

Flexible and rigid-flex PCBs are expanding into foldable phones, wearables, and medical devices. These designs unlock form factors impossible with traditional rigid boards.

The Talent Gap Is Real

This demands expertise in:

- Thermal modeling

- High-frequency layout

- Advanced materials science

Professionals with these skills are in high demand and short supply.

Win2uit’s approach: We invest heavily in training and equipment capable of handling advanced packaging and HDI work. We don’t just assemble boards; we help OEMs navigate design-for-manufacturing tradeoffs that impact yield and cost. That expertise matters more as boards get denser and tolerances tighten.

Trend 4: Sustainability Is Moving from Marketing to the Manufacturing Floor

Customers want sustainable electronics. Not just incremental performance gains, but products designed for longevity, repairability, and end-of-life recycling.

What’s Actually Changing in Production:

- Halogen-free laminates replacing traditional materials

- Biodegradable substrates for specific applications

- Closed-loop water systems reducing consumption

- Modular designs allowing component upgrades vs. full replacement

Europe leads on regulatory pressure through ESG compliance requirements, but North American and Asian markets are following.

The Investment Reality

Initial sustainability investments increase expenses. The payoff comes through:

- Reduced energy consumption

- Improved brand reputation

- Compliance with tightening regulations

- Reduced material waste

Early movers will be better positioned than those waiting for mandates.

At Win2uit, we’re implementing sustainable practices not because they’re trendy but because customers are demanding them in RFQs. Material selection conversations now routinely include environmental impact alongside electrical performance.

This isn’t going away.

Trend 5: Automation Separates Leaders from Followers

Smart manufacturing isn’t a buzzword. It’s operational reality.

Factories integrate IoT sensors, robotics, and data analytics to create intelligent, adaptive production environments.

What Automation Delivers by 2026:

By 2026, half of companies with intra-logistics robots will have multi-agent orchestration systems managing complex interactions.

Quality improvements:

- AI-powered automated optical inspection (AOI) catches defects humans miss

- Real-time thermal monitoring prevents board failures

- X-ray inspection validates internal solder joints in dense assemblies

Efficiency gains:

- Reduced human error

- Faster design-to-production cycles

- Improved first-pass yield rates

- Lower scrap and rework costs

The Platform Challenge

Manufacturing execution systems must handle thousands of machine interactions per hour. The platform orchestrating them needs to be robust, scalable, and AI-ready.

Win2uit’s MES platform manages this complexity daily. We’ve automated inspection protocols that used to require manual review, freeing skilled technicians for higher-value tasks while improving quality metrics.

The upfront investment was significant. The operational advantage is permanent.

Key insight: Automation isn’t about replacing people. It’s about elevating what skilled workers can accomplish.

Trend 6: Prototyping Speed Became a Competitive Weapon

Time-to-market pressure is intensifying. Consumer electronics refresh cycles compressed to six months in some categories.

Rapid prototyping isn’t a luxury, it’s competitive requirement.

How 3D Printing Changed the Game:

3D printing is transforming PCB prototyping:

- Same-day turnarounds at roughly $100 per prototype

- Complex geometries impossible with traditional methods

- Reduced risk before committing to volume manufacturing

- Faster iteration cycles for design validation

Nano Dimension pioneered 3D-printed circuit boards for aerospace, enabling custom form factors and rapid testing.

The Bottleneck Nobody’s Fixing

AI hardware startups face 7-9 week lead times for small-batch HDI work in traditional supply chains. Manufacturers offering rapid prototyping services capture this work.

Win2uit has invested in rapid prototyping capabilities specifically to support customers in compressed development cycles. When an OEM needs five iterations tested in two weeks, traditional lead times kill projects.

We’ve built our processes to accommodate that reality.

The Challenges Nobody's Solving Yet

Growth opportunities come with real obstacles. Here’s what keeps us up at night:

Material Scarcity

Copper foil, specialty resins, and halogen-free laminates face supply constraints. A recent report warns that water scarcity could disrupt copper production in Chile by 2035, threatening PCB material availability.

Talent Shortage

Demand for engineers skilled in thermal modeling, high-frequency design, and AI-enhanced workflows outpace supply. Without investment in training programs, innovation slows and error rates rise.

Quality at Scale

As boards grow denser and layer counts increase, traditional inspection methods can’t keep up. Advanced tools like AI-powered AOI and real-time thermal monitoring are essential but are not universally accessible, especially for smaller manufacturers.

Supply Chain Fragility

Despite nearshoring efforts, most companies lack the digital infrastructure for truly connected operations. End-to-end visibility remains elusive.

Win2uit’s position: We face these challenges too. We’ve addressed some through investment in automation and training. Others, like material availability, require industry-wide solutions that don’t exist yet. Acknowledging these constraints is more useful than pretending they’re solved.

What Actually Matters for 2026

The electronics manufacturing landscape rewards agility, technical depth, and strategic foresight.

Companies Thriving in 2026 Will:

- Deploy AI and automation to improve yield, reduce downtime, and enable predictive quality control

- Diversify manufacturing footprints to balance cost with supply chain resilience

- Develop specialized expertise in advanced packaging, flexible PCBs, and high-layer-count boards

- Implement sustainability as competitive differentiation, not a compliance checkbox

- Shorten iteration cycles through rapid prototyping and design-for-manufacturing collaboration

The fundamentals haven’t changed: customers want quality, speed, and value.

But the tools, processes, and geographic strategies delivering those outcomes are evolving fast.

The Win2uit Difference: Execution Over Prediction

At Win2uit, we’re not predicting trends. We respond to them daily in customer programs.

Our investments in automation, nearshore capacity, and rapid prototyping aren’t strategic positioning. They’re operational requirements for serving OEMs navigating this landscape.

What we’ve built:

- AI-powered quality control systems handling thousands of inspections hourly

- Nearshore operations delivering 40% faster turnaround than offshore alternatives

- Rapid prototyping capabilities supporting compressed development cycles

- Advanced packaging expertise for HDI and high-layer-count boards

- Sustainable manufacturing practices meeting evolving customer requirements

Manufacturers who adapt will capture growth. Those who wait will watch it happen elsewhere.

The difference isn’t vision. It’s execution.

Ready to Navigate 2026's Manufacturing Challenges?

Win2uit specializes in precision PCB assembly and contract manufacturing services. Our advanced capabilities, nearshore operations, and commitment to quality help OEMs navigate the evolving electronics manufacturing landscape.

Let’s discuss how we can support your next project.

About Win2uit

Win2uit is a leading electronics contract manufacturer specializing in precision PCB assembly, box build, and end-to-end supply chain management. With advanced automation, nearshore operations, and deep technical expertise, we help OEMs bring complex products to market faster and more efficiently.