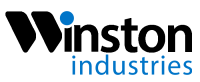

Custom Cable Assembly and Wire Harnesses

In any electrical system, power is only as reliable as the connections that carry it. Even the most sophisticated components will fail if wiring isn’t properly organized, protected, and routed. Electrical failures can be costly, causing system downtime, safety hazards, or even total project delays. That’s why custom cable assemblies and custom wiring harnesses are essential for industries where performance, reliability, and safety are non-negotiable.

These are not off-the-shelf solutions. They are precision-engineered systems designed to simplify installation, improve durability, maintain signal integrity, and ensure compliance with industry standards. At Win2uit, we deliver tailored connectivity solutions that support applications ranging from aerospace to industrial automation, helping clients tackle complex wiring challenges while meeting the highest quality standards.

Win2uit Cable and Harness Capabilities

Our manufacturing capabilities are designed to meet diverse customer needs:

- High-mix, low- to mid-volume production

- Customized cable assemblies and wiring harnesses

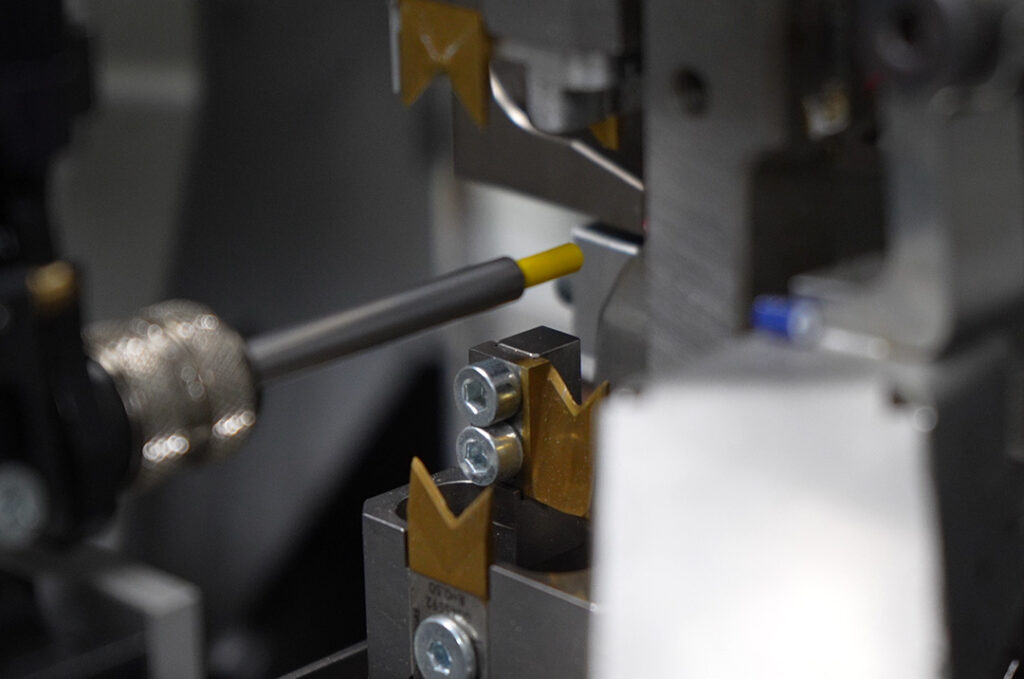

- KOMAX wire processing with crimp & seal insertion

- Wire-to-wire and wire-to-board assemblies

- Top-tier connectors and crimp terminals from Molex, TE, and others

- Jacketed cable types: coaxial, flat ribbon, multicolor

- Molex, TE, and other premium connectors

These capabilities enable solutions that are precisely engineered, robust, and compliant.

The Win2uit Advantage

Why Win2uit? We combine expertise, manufacturing capabilities, and quality assurance:

- Comprehensive testing: continuity, insulation, high-pot

- Scalable production from prototypes to large orders

- Proven results: faster assembly, fewer failures

- Stocked UL-rated wires and jacketed cable types

- USA-based manufacturing in Louisville, Kentucky

Win2uit Cable Assembly Design and Production Process

- Consultation & Design: Assess requirements, environment, and compliance.

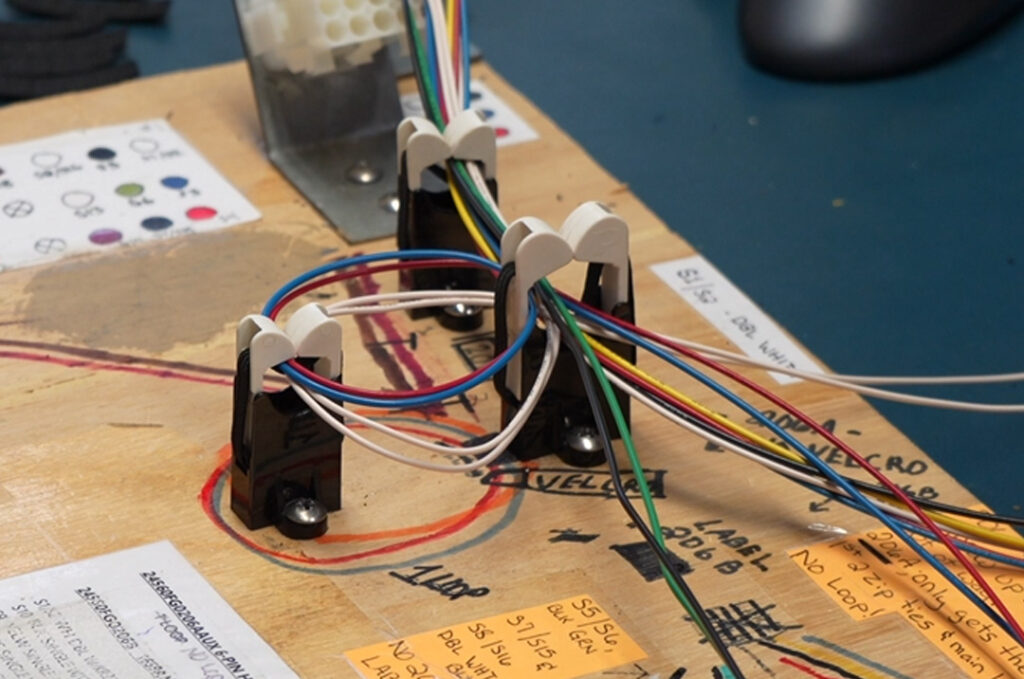

- Prototyping: Rapid iterations with CAD layouts and material selection.

- Engineering & Validation: Optimize strain relief, shielding, and connectors.

- Production: High-mix/low-mid volume runs with automated KOMAX processing.

- Testing & QA: End-to-end testing ensures all assemblies meet specifications.

- Delivery & Support: Pre-labeled, plug-and-play assemblies with full documentation.

What is a Custom Cable Assembly?

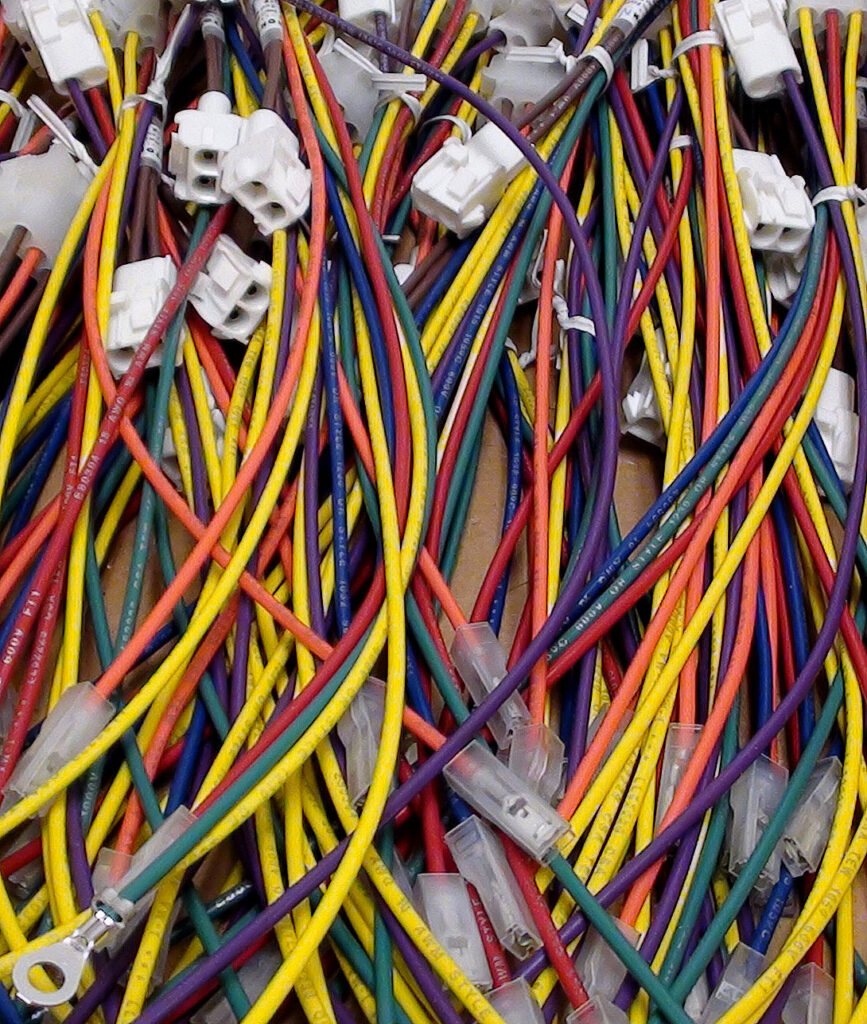

Custom cable assemblies are a group of electrical wires or cables bundled into a single, cohesive unit. These assemblies are enclosed in protective sheathing and terminated with connectors specifically chosen to match your system’s design. They are can be built to handle environmental stresses, signal integrity challenges, and regulatory requirements.

How Cable Assemblies Are Designed

- Material Selection: The assembly’s purpose determines the best conductor materials (copper, tinned copper, or specialty alloys) and insulation types (PVC, Teflon, silicone) based on temperature, chemical exposure, flexibility, and regulatory requirements.

- Shielding: Foil, braid, or combination shields are added to prevent EMI/RFI interference, ensuring clean signal transmission.

- Connector Termination: Each end is terminated with connectors designed for the specific device or interface, from Molex and TE to MIL-Spec options.

- Assembly & Testing: Cables are bundled, sheathed, labeled, and tested for continuity, insulation resistance, and voltage tolerances.

Common Uses

Harsh industrial environments

High-temperature machinery

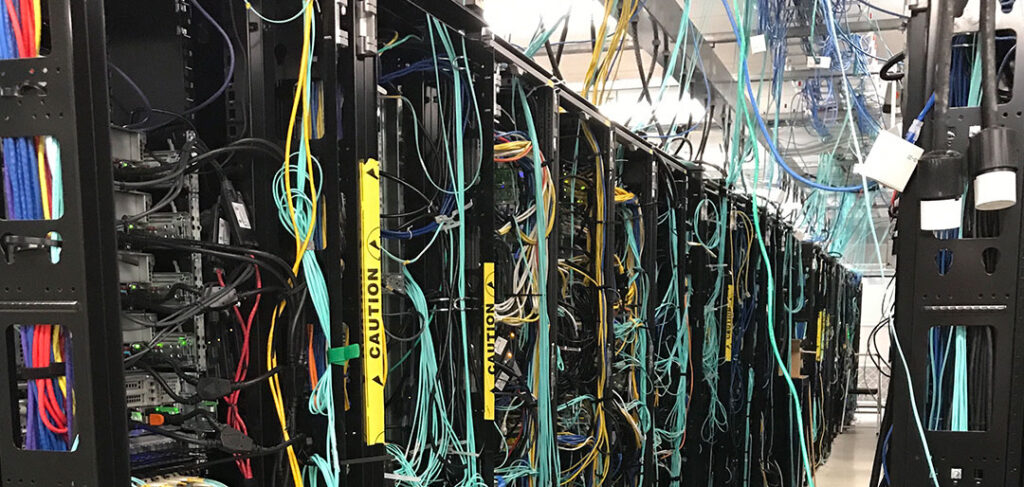

Data centers and telecom racks

Transportation and automotives

Medical devices and laboratory equipment

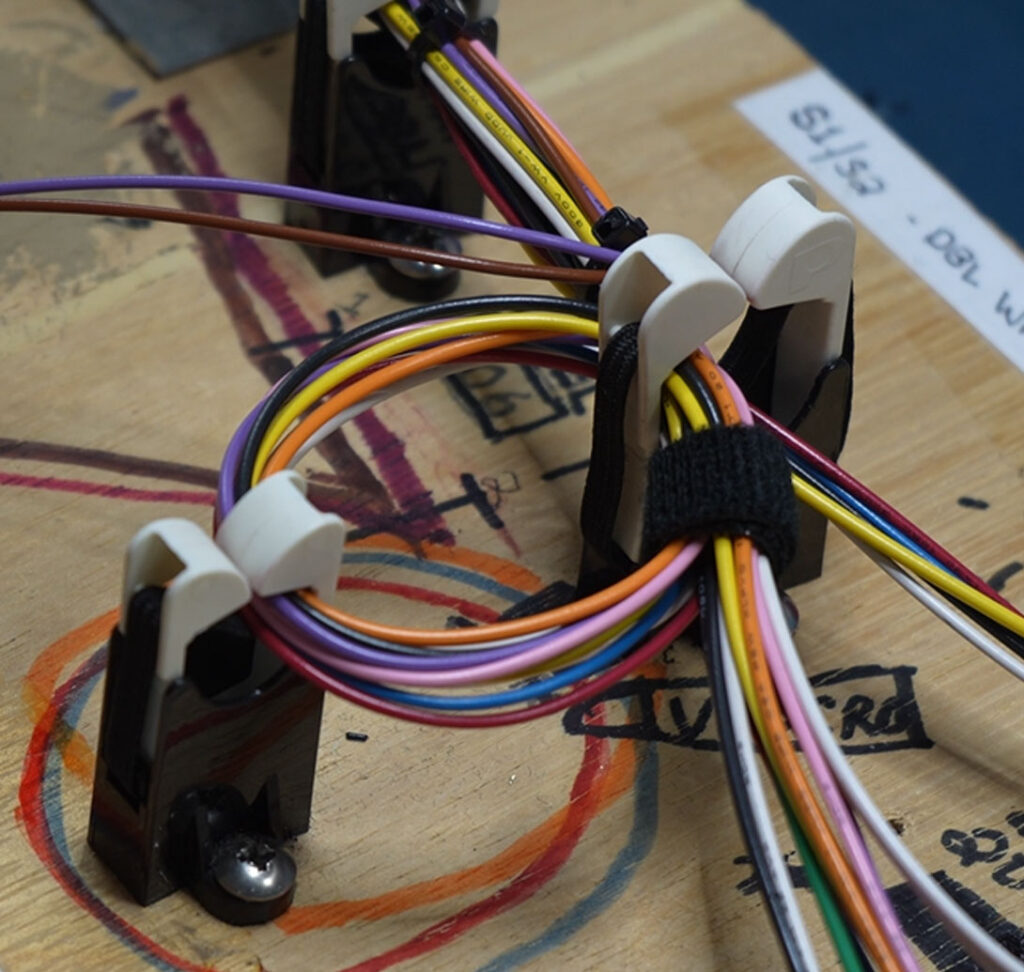

What is a Custom Wiring Harness?

A custom wiring harness is a made-to-order assembly of wires, terminals, and connectors engineered to route electrical power or signals precisely where needed. Unlike cable assemblies, harnesses are optimized for organization, flexibility, and efficient installation in complex systems.

Benefits of Wiring Harnesses

- Organized Routing: Eliminates guesswork and reduces clutter in panels and enclosures.

- Reduced Installation Errors: Pre-labeled wires and connectors reduce human error and troubleshooting time.

- Durability: Sleeving, protective wraps, grommets, and strain reliefs protect wires from abrasion, bending, or environmental stress.

Common Uses

- Factory automation and robotics

- Automotive dashboards and control panels

- Consumer electronics and appliances

- Medical monitoring and surgical devices

Cable Assembly vs. Wiring Harness Assembly: Key Differences

While often used interchangeably, these solutions serve distinct purposes:

| Feature | Custom Wiring Harness | Custom Cable Assembly |

|---|---|---|

| Primary Purpose | Organize and route wires efficiently | Protect and connect in harsh environments |

| Environmental Protection | Minimal; can add sleeving/shielding | High; durable sheathing, EMI/RFI shielding, seals |

| Durability | Moderate; suitable for controlled settings | High; can be designed for mechanical, thermal, and chemical stresses |

| Complexity | Simplifies installation | Handles multiple cables/signals within one rugged unit |

| Common Uses | Dashboards, panels, appliances | Aerospace, industrial robotics, telecom |

Key Benefits of Custom Connectivity

Investing in custom cable assemblies and custom wiring harnesses offers measurable advantages:

- Enhanced Durability

Custom solutions are designed for vibration, abrasion, moisture, heat, chemicals, and mechanical stress. This ensures longer operational life, fewer replacements, and reduced maintenance costs.

- Improved Performance & Reliability

Shielding and proper conductor selection reduce signal loss, EMI, and RFI, increasing uptime and system reliability.

Example: Data center fiber-optic assemblies maintain low-latency, high-speed transmission without interruptions.

- Faster Installation & Reduced Labor Costs

Pre-labeled, pre-tested assemblies are plug-and-play ready, saving hours of assembly time and minimizing human error.

- Optimized Space & System Aesthetics

Custom lengths and routing reduce excess slack, optimize airflow in enclosures, and make service easier and safer.

- Reduced Risk & Downtime

Precision routing and robust construction prevent shorts, control faults, and field failures.

- Regulatory Compliance

Win2uit ensures all assemblies meet UL, RoHS, ISO, or MIL-Spec requirements, avoiding costly redesigns or certification delays.

Industries That Rely on Custom Connectivity

Custom assemblies and harnesses are essential across industries:

- Automotive & Transportation: Infotainment, safety systems, engine controls

- Medical & Healthcare: Diagnostic devices, surgical robotics, patient monitoring

- Aerospace & Defense: Lightweight, MIL-Spec, vibration-resistant assemblies

- Industrial Automation: PLCs, robotics, harsh plant environments

- Telecommunications: Fiber-optic networks, wireless infrastructure

- Consumer Electronics: Smart devices, gaming, compact electronics

- Renewable Energy: Solar, wind, and battery storage systems

- Test & Measurement: Low-noise, shielded assemblies for accuracy

Each industry faces unique challenges. Win2uit delivers solutions engineered for environmental stress, precise routing, and long-term reliability.

Compliance & Industry Standards

Win2uit designs connectivity solutions that meet stringent requirements:

- UL Certification: Fire resistance, voltage tolerance, insulation reliability

- RoHS Compliance: Free from hazardous substances like lead, mercury, and cadmium

- MIL-Spec Standards: Extreme durability for aerospace and defense

- ISO 9001: Quality, traceability, and continuous improvement

- IPC/WHMA-A-620: Workmanship standards for cable and wire harness assemblies

All assemblies come with full documentation and batch tracking, ensuring compliance from prototype to production.

Emerging Trends in Custom Connectivity

New technologies are raising the stakes for wiring solutions:

- Electric Vehicles (EVs): High-voltage, heavy-current harnesses for batteries

- Robotics: Flexible harnesses that endure repeated motion

- IoT & Smart Devices: Compact, high-speed assemblies for connected devices

- Renewable Energy: Weatherproof, long-life assemblies for solar and wind farms

- High-Speed Data: Shielded assemblies for 5G and fiber-optic networks

Custom connectivity is now a mission-critical component of modern systems.

Build Better Connections

Your system is only as strong as its weakest connection. With custom cable assemblies and custom wiring harnesses from Win2uit, every signal is secure, every volt is delivered, and every connection performs reliably.

Partner with Win2uit to reduce downtime, speed installation, and meet compliance standards, delivering systems that are on time, on budget, and built to last.