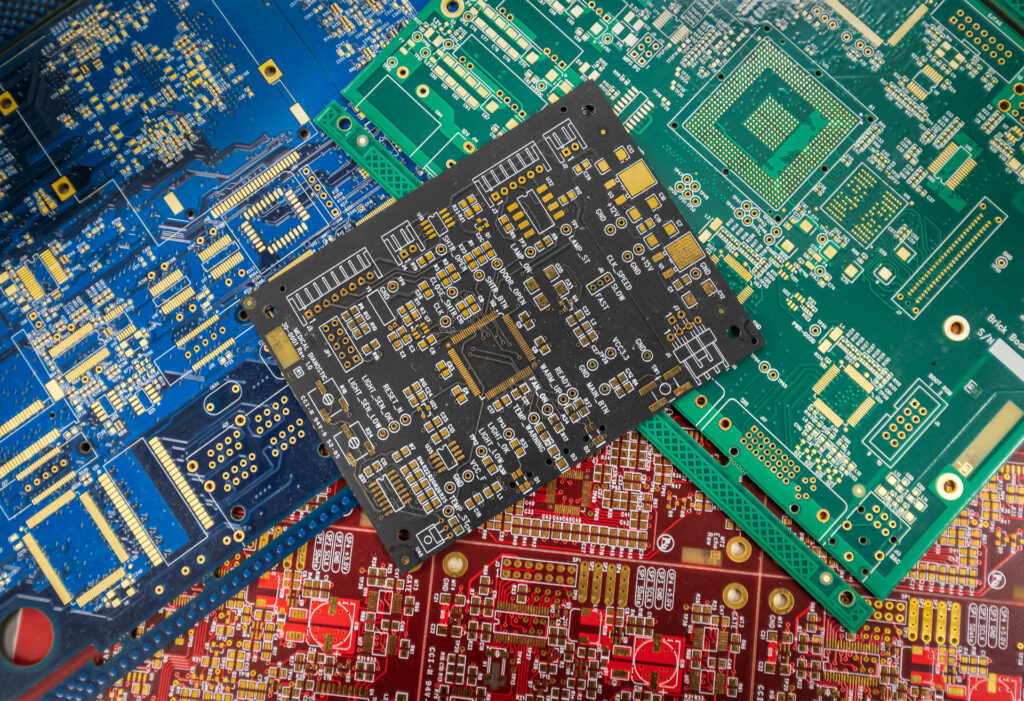

Multi-color Printed Circuit Boards (PCBs), also known as multi-layered or multi-level PCBs, are PCBs that utilize multiple layers of different colored substrates. These layers are stacked together to create a PCB with distinct sections or areas of diverse colors. The colors are typically added during the manufacturing process by incorporating colored laminates or coatings between the layers of the PCB.

Why Use Multi-Colored PCBs?

The decision to use a multi-color PCB depends on the specific requirements of your project and the desired aesthetics. Here are some factors to consider when deciding whether a multi-color PCB is necessary for your application:

Functional Requirements – Evaluate the functional requirements of your PCB. A multi-color PCB might be beneficial if color coding is essential for distinguishing different functional sections or specific components.

Circuit Complexity – A single-color PCB may be sufficient for simple circuits with straightforward functionality. However, color coding can aid in visual organization and troubleshooting for complex circuits with multiple components or subsystems.

Assembly and Maintenance – Consider whether color-coding could simplify the assembly process or make identifying and replacing components during maintenance or repairs easier.

Aesthetics and Branding – If the PCB’s appearance is a priority or aligns with specific branding requirements, a multi-color PCB can be used for visual appeal.

Documentation and Communication – Color-coding on the PCB can be a helpful visual aid for documentation. It can make understanding schematics, assembly instructions, and other technical documentation easier.

Industry Standards – Some industries or applications may have standards or regulations that recommend or require specific color-coding for safety, functionality, or compliance reasons.

Customization – If customization and a unique visual design are essential for your product, a multi-color PCB can provide opportunities for creativity and differentiation.

Multi-Color PCBs Aren’t Always the Best Choice

Cost Considerations – Introducing multiple colors to a PCB can add to the manufacturing cost. Consider whether the benefits of multi-color functionality and aesthetics outweigh the additional expenses.

Practicality – Evaluate whether using multiple colors is practical and enhances the PCB’s overall usability and functionality. In some cases, a single-color PCB may be more practical and cost-effective.

It’s important to note that the color of the solder mask, which is the protective layer covering the PCB, can be customized. While the traditional color is green, other colors, including red, blue, black, and white, are also common. The solder mask color does not affect the electrical performance of the PCB but can influence its appearance.

In summary, the decision to use a multi-color PCB depends on your project’s specific requirements, including functionality, documentation needs, aesthetics, and industry standards. Consider consulting with your PCB manufacturer to discuss the feasibility, cost implications, and potential benefits of incorporating multiple colors into your PCB design.