Win2uit Surface Mount Technology (SMT) Capabilities:

Precision, Speed, and Reliability

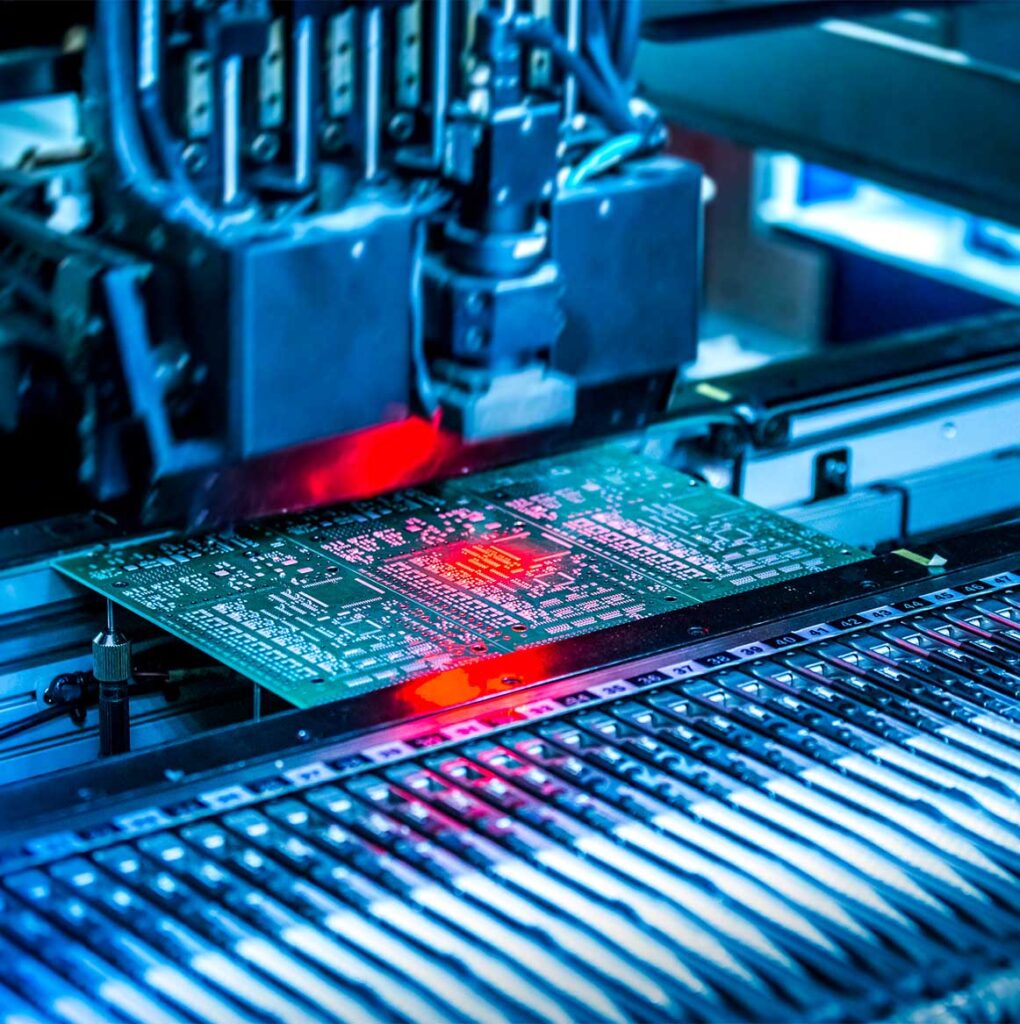

Surface-mount Technology (SMT) has transformed electronics manufacturing, delivering faster production, smaller designs, and superior performance. For companies across industries, surface mount technology isn’t just about assembling components; it’s about building reliable products at scale. Win2uit provides advanced SMT solutions that balance speed, precision, and quality. From prototype to full-scale production, our capabilities help customers bring their innovations to life while reducing costs and accelerating time-to-market.

Electronics manufacturing has grown increasingly complex, with smaller, more powerful devices expected to do more in less space. Surface mount technology is at the heart of this innovation, making it possible to assemble intricate designs at scale while maintaining excellent reliability. For customers, this means faster product launches, higher yields, and products that perform consistently in demanding environments. For Win2uit, it’s an opportunity to deliver value where speed, quality, and precision converge.

Our deep expertise in Surface Mount Technology enables us to serve a diverse range of industries, including medical devices, automotive, aerospace, industrial electronics, and military applications. For quality assurance, our processes follow globally recognized IPC standards for electronics manufacturing reliability.

Why Surface Mount Technology Matters

Surface Mount Technology has become the industry standard because it enables more compact, lightweight, and efficient PCBs. Unlike traditional through-hole assembly methods, SMT mounts components directly onto the surface of a PCB, allowing higher component density and modern, miniaturized designs.

Key benefits of SMT include:

- Compact Designs: Smaller components take up less space, enabling more features on the same board size.

- High-Speed Assembly: Automated placement and soldering processes increase throughput and reduce labor costs.

- Design Flexibility: SMT can accommodate complex boards with mixed component sizes and types.

- Reliability: Reduced mechanical stress and precise soldering enhance product longevity.

Win2uit’s expertise in Surface Mount Technology ensures that our clients can take full advantage of these benefits while maintaining high yields and fast turnaround times. Whether you are designing a high-density consumer device or a rugged industrial controller, this process enables the precision and performance required for these applications.

Win2uit SMT Capabilities

Win2uit leverages state-of-the-art Surface Mount Technology equipment and processes to ensure PCB assembly accuracy, consistency, and speed.

Our SMT services include:

- Automated Pick-and-Place Machines: High-speed placement of thousands of components per hour, including fine-pitch devices and complex BGAs.

- Precision Solder Paste Printing: Advanced stencil printing ensures consistent solder deposition for strong, reliable joints. After printing, a 2D inspection of the paste deposit is performed to ensure the correct amount is applied.

- Reflow Soldering: Multi-zone ovens provide controlled heating and cooling to prevent defects and optimize soldering.

- Automated Optical Inspection (AOI): Detects component misplacement, missing parts, or solder imperfections, reducing post-production rework.

- Flexible Component Handling: Supports a wide range of SMT components, from 01005 micro-components to larger packages.

- Mixed Technology Capability: SMT and through-hole assembly combined in a single process when needed.

- Prototype to Production Scalability: Capable of supporting both low-volume pilot runs and high-volume manufacturing.

Each capability contributes to higher quality, faster production, and reliable outcomes for our clients. By combining precision equipment with experienced operators, Win2uit delivers consistent results that help reduce costs and improve product performance. Our processes align with global standards, such as those outlined by the IEEE.

Looking for a partner to scale

your PCB production?

The Workflow at Win2uit

Our proven process ensures every PCB assembly meets the highest standards:

Step 1: Design for Manufacturability (DFM)

Our experts review Gerber files and BOMs to identify potential assembly challenges. DFM feedback ensures your design is optimized for SMT, reducing defects and minimizing assembly issues.

Step 2: Material Procurement

Our supply chain team sources components efficiently, ensuring lead-time reliability and component quality. We leverage strong industry relationships for hard-to-find or custom parts to maintain supply continuity.

Step 3: Stencil & Paste Printing

Precision stencil printing deposits solder paste exactly where it is required. Proper paste deposition is crucial for forming robust and reliable solder joints during reflow.

Step 4: Pick-and-Place Assembly

Automated pick-and-place machines position components with micron-level accuracy. Cameras and fiducial recognition ensure precise orientation for even the smallest parts.

Step 5: Reflow Soldering

Boards are passed through reflow ovens with customized profiles, accommodating various board thicknesses, copper layouts, and component sizes. This ensures solid solder connections without component damage.

Step 6: Delivery & Integration

Completed boards are packaged and delivered ready for system integration. To support end-to-end assembly needs, we offer additional services such as conformal coating, box build, and wire harness integration.

This workflow allows Win2uit to handle complex projects efficiently while maintaining strict quality control.

Advanced Techniques

Win2uit continuously adopts the latest Surface Mount Technology innovations to meet evolving industry demands:

- Fine-Pitch Component Assembly – Precision placement of components with pitches under 0.5mm.

- Double-Sided Assembly – Efficiently mount components on both sides of the PCB.

- Conformal Coating – Protective coatings improve environmental resistance and long-term reliability.

- Selective Soldering – Integrates through-hole components into SMT processes efficiently.

- RoHS-Compliant Processes – Environmentally friendly soldering and component handling.

- AI-Enhanced Inspection – Leveraging machine learning for defect detection and predictive quality analytics.

These innovations allow Win2uit to support high-density, high-reliability electronics across industries, including medical, automotive, aerospace, industrial, and military.

Why Choose Win2uit?

Win2uit stands out in the industry by combining technology, expertise, and customer focus:

- Fit, Form, and Function – Every board meets design intent and performs reliably.

- End-to-End Services – From prototyping to box build and wire harness integration.

- Flexible Production – Scalable processes accommodate both low and high-volume runs.

- Speed to Market – Domestic U.S. production enables faster turnaround and delivery.

- Cost Efficiency – Lean manufacturing and intelligent sourcing reduce total cost.

- ISO-Certified Quality – Ensures consistent, high-quality SMT assemblies.

Choosing Win2uit means partnering with a company that prioritizes precision, reliability, and customer success.

Ready to launch your

next PCB project?

Getting Started with Win2uit

Step 1: Request a Quote – Share your Gerber files and BOM to receive a detailed feasibility and cost analysis with DFM recommendations.

Step 2: Prototype and Pilot Runs – We conduct small-scale production runs to validate assembly processes and performance.

Step 3: Inspection and Rework – AOI, X-ray, and functional testing ensure every board meets specifications. Intelligent rework efficiently corrects any defects.

Step 4: Full-Scale Production – Once validated, we scale production, maintaining consistent quality across all units.

Step 5: Post-Production Support – Conformal coating, box build, lifecycle support, and integration services complete the offering, providing a full-service solution from design to delivery.

FAQs About Surface Mount Technology

SMT is a process where components are mounted directly onto the PCB surface, enabling compact designs and faster production.

Surface Mount Technology is widely used in medical devices, automotive, aerospace, consumer electronics, industrial systems, and defense.

SMT allows higher component density and smaller designs, while through-hole is typically used for larger or high-stress components.

Yes. Our processes are scalable from early prototypes to full production.

We have the latest technology with incoming inspection equipment, link to our ERP system, X-Ray counting, and Smart racks to dynamic holding of parts.

Surface Mount Technology is essential for modern electronics design. Win2uit combines advanced equipment, expert technicians, and ISO-certified processes to deliver high-quality, reliable PCB assemblies. Our services support rapid prototyping, complex designs, and full-scale production across multiple industries.

With Win2uit, companies gain a partner committed to precision, speed, and reliability. From design assistance to full production and post-assembly services, we ensure your products are ready to perform in any application.

Let’s talk today to leverage our Surface Mount Technology expertise for your next project.