Win2uit: Your Partner for Conformal Coating Services

Electronics are increasingly integrated into devices and systems that are exposed to demanding environments. From automotive to aerospace, military to medical industries, the need for reliable, durable, and efficient electronic components has never been greater. One of the most effective ways to ensure the longevity and performance of these components is through the application of conformal coatings.

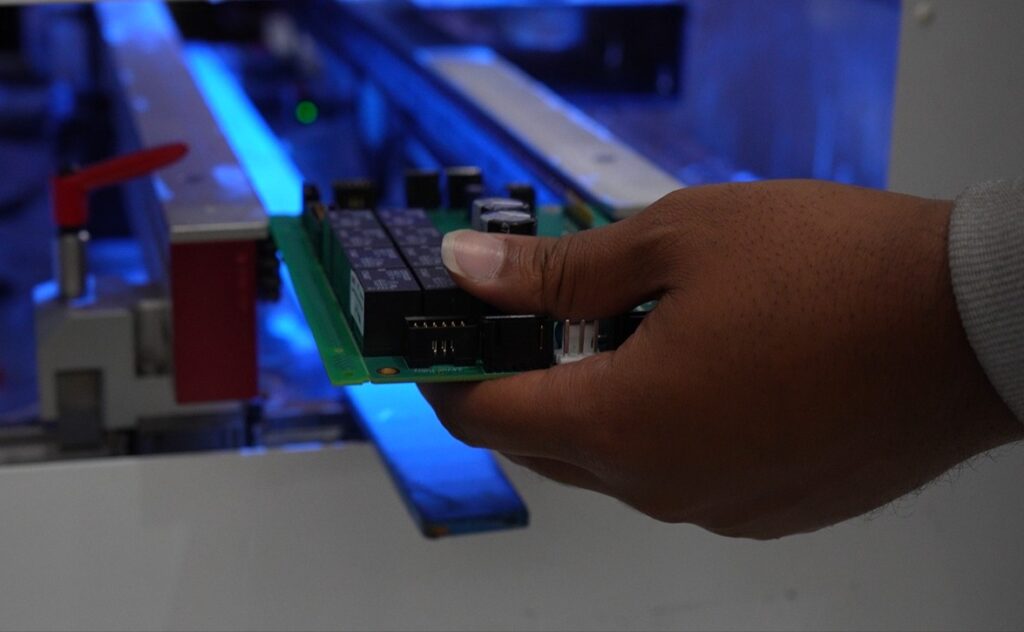

At Win2uit, we specialize in providing high-quality coating services to protect electronic components from harsh environmental conditions. We understand that every electronic device has unique requirements, and we offer customized coating solutions that suit our clients’ specific needs. Our state-of-the-art facilities and advanced application techniques ensure that your components receive the highest level of protection available in the industry.

Why Choose Win2uit Conformal Coating Services?

- Expertise and Experience: With years of experience in the industry, Win2uit has a team of experts who are well-versed in the science of coating electronics. Our technicians have extensive knowledge of the different types of coatings and their applications, allowing us to offer the best solution for your needs.

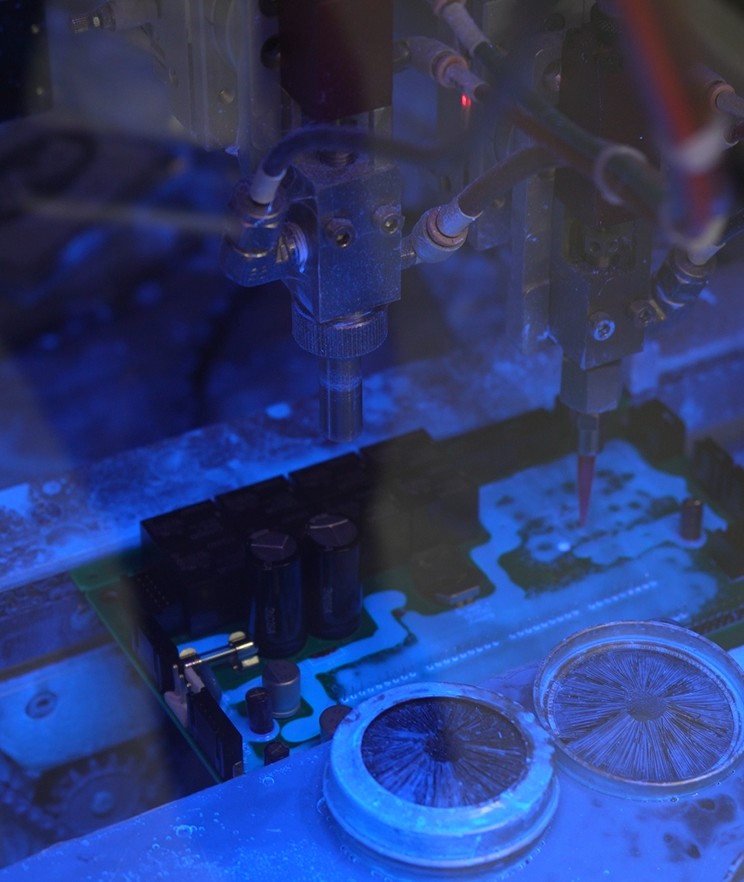

- High-Quality Coatings: At Win2uit, we use HumiSeal® 1B73, a high-quality material, to ensure maximum protection for your components. Its excellent dielectric properties and fast-drying nature make it ideal for high-reliability electronic applications. We use an automated system to apply the coating to guarantee accurate coverage. HumiSeal® 1B73 offers ease of rework and repairability, making it a popular choice in both prototyping and high-volume manufacturing environments.

- Durability and Reliability: Win2uit’s coating services are designed to enhance the longevity and performance of your electronics. Our coatings provide a durable, reliable solution that will withstand the rigors of harsh environments, ensuring that your devices continue to operate at peak performance over time.

Applications of Conformal Coating in Different Industries

The versatility of conformal coatings makes them suitable for a wide range of industries. Here are a few examples:

- Automotive Industry: The automotive industry relies heavily on electronic components for safety systems, infotainment, navigation, and other critical functions. Conformal coatings protect automotive electronics from moisture, chemicals, and high temperatures, ensuring that systems operate smoothly in demanding environments.

- Aerospace and Defense: In aerospace and defense, electronic components must withstand extreme conditions, including high altitudes, rapid temperature changes, and exposure to harsh chemicals. Conformal coatings offer robust protection for sensitive electronics used in aircraft, satellites, and military devices.

- Medical Devices: Medical devices must meet strict safety and reliability standards, as they often operate in environments where failure is not an option. Conformal coatings help protect medical electronics from moisture, contamination, and other environmental hazards, ensuring they remain reliable and effective.

- Consumer Electronics: From smartphones to wearables, consumer electronics are subjected to wear and tear from everyday use. Conformal coatings provide an extra layer of protection against moisture, dust, and other elements that can degrade performance.

Industrial Electronics: Industrial electronics are exposed to a wide range of challenging conditions, from high humidity and temperature fluctuations to exposure to chemicals and dust. Conformal coatings ensure these components continue to function reliably, reducing downtime and maintenance costs.

Conformal coatings are a vital aspect of modern electronics, providing a protective barrier that shields sensitive components from moisture, chemicals, dust, and other environmental factors. Without this protective layer, electronic boards and components are susceptible to damage, which can lead to failures, downtime, or costly repairs. The coating is applied in a thin, uniform layer that conforms to the surface of the electronic components, hence the term “conformal.”

What is Conformal Coating?

Conformal coating refers to a protective layer applied to the surface of printed circuit boards (PCBs) and other electronic components. The material is designed to conform to the shape of the underlying components, offering insulation, moisture resistance, and protection from contaminants. The application of conformal coatings is essential in environments where the electronics are exposed to extreme conditions, such as high humidity, temperature fluctuations, or the presence of chemicals and dust.

There are various types of conformal coating materials, but at Win2uit Electronics we utilize acrylic conformal coatings due to their proven versatility and reliability across a wide range of industries. These coatings provide dependable protection for printed circuit boards against moisture, dust, and chemical contaminants, ensuring consistent performance in even the most demanding environments. Known for their excellent electrical insulation properties and ease of application, acrylic coatings are widely used in consumer electronics, automotive systems, industrial controls, and more. Win2uit leverages this technology to deliver durable, high-quality electronic assemblies that meet stringent performance standards while remaining easy to inspect, repair, or rework when needed.

The Importance of Conformal Coating in Electronics

- Protection Against Moisture: One of the primary functions of conformal coatings is protecting electronic components from moisture. Water and high humidity can lead to corrosion, short circuits, and general degradation of sensitive components. By forming a moisture-resistant barrier, conformal coating helps prevent these issues, ensuring the reliability of electronic devices in wet or humid environments.

- Shielding from Dust and Debris: Dust, dirt, and other contaminants can infiltrate electronic devices and cause malfunctions. In industrial, automotive, and other rugged environments, exposure to dust is inevitable. Conformal coatings act as a protective layer, preventing debris from entering the electronics and causing damage. This makes the coating essential for devices used in environments such as factories, construction sites, and outdoor applications.

- Chemical Resistance: Electronic devices are often exposed to chemicals, oils, and solvents that can damage components. Conformal coatings, especially polyurethane and epoxy types, offer resistance to a wide range of chemicals, ensuring that electronics continue to function optimally even when exposed to harsh substances. This is especially important for industrial, military, and automotive applications where exposure to chemicals is common.

- Prevention of Corrosion: Metal components in electronic devices are susceptible to corrosion when exposed to moisture, chemicals, or salt. Conformal coatings provide a protective barrier that prevents corrosion, preserving the integrity and functionality of the components. This is especially vital for electronics used in maritime, automotive, and military industries, where exposure to corrosive elements is frequent.

- Enhanced Durability and Longevity: The thin, protective layer of a conformal coating helps to extend the life of electronic components by shielding them from environmental stresses. This added durability means fewer repairs, reduced downtime, and lower replacement costs over time, making conformal coatings an investment in the longevity of electronic products.

Conformal coating is a critical process for protecting sensitive electronic components in various industries. The thin, protective barrier creates shields electronics from moisture, dust, chemicals, and other environmental factors that can cause damage. By extending the life of electronic devices, improving reliability, and reducing repair costs, conformal coatings are an invaluable asset for businesses and industries that rely on electronic technology.

At Win2uit, we provide expert conformal coating services to ensure your electronic components are adequately protected. With our high-quality materials, advanced application techniques, and personalized solutions, we are your trusted partner for all your conformal coating needs. Whether you’re in the automotive, aerospace, medical, or industrial sectors, Win2uit can help safeguard your electronics and ensure their optimal performance in even the harshest environments.

Conformal coating is a thin protective polymer layer applied to printed circuit boards (PCBs) and electronic assemblies to protect them from moisture, dust, chemicals, and temperature extremes.

It increases product reliability by preventing corrosion, short circuits, and environmental damage, especially in harsh or high-humidity conditions.

Automotive, aerospace, military, consumer electronics, industrial controls, marine, and medical devices commonly use it to enhance durability.

The most common types are:

Acrylic (AR) – Easy to apply/remove, good general protection.

Silicone (SR) – Flexible, great for extreme temperature ranges.

Polyurethane (UR) – Excellent chemical resistance.

Epoxy (ER) – Very durable but harder to remove.

Parylene (XY) – Vapor-deposited for superior protection and uniform coverage.

At Win2uit, we use HumiSeal® 1B73, a high-quality material, to ensure maximum protection for your components.

Common methods include brushing, spraying, dipping, and vapor deposition (Parylene).

Usually between 25–250 microns (0.001–0.010 inches), depending on the type and application.

Yes, but the ease of rework depends on the coating type — acrylics are the easiest, while Parylene and epoxies are more challenging.

Minimal, if applied correctly. However, thicker layers or certain materials can slightly reduce thermal transfer.

Components like connectors, switches, or heat sinks are masked using tapes, plugs, or removable masking compounds before coating.

Techniques include UV light inspection (for UV-trace coatings), visual inspection, and automated thickness measurement tools.

Many are, but always check the product datasheet to ensure compliance with environmental regulations.

Silicone and Parylene are often used for high-heat, high-moisture, or corrosive environments, while polyurethane is best for chemical resistance.

Costs vary based on coating type, application method, and masking requirements — typically a small fraction of the total PCB cost, but can be higher for specialized coatings like Parylene.

Many manufacturers use it as part of their strategy to reduce failures and extend warranty coverage.

Consider the operating environment, regulatory requirements, rework needs, and budget. Consulting with a coating specialist or manufacturer is recommended.